Solid Carbide High Performance Step Twist Drill Bits for Metal Drilling

Description

Basic Info.

| Model NO. | eitfs4082 |

| Suitable for | Coper.Cast Iron.Carbon Steel.Mould Steel |

| Machine Type | Miling Machine |

| Shank Diameter | 4-40mm |

| Over All Length | 38-330mm |

| Coating | Tiain /Aitin |

| Flute Diameter | 0.3-40mm |

| Transport Package | One Plastic Pipe Packs One Piece, 10 Pieces Per Gr |

| Specification | Tungsten Cobalt Alloy, Tungsten Carbide |

| Trademark | eitfs |

| Origin | Jiangsu, China (Mainland) |

| HS Code | 8208101900 |

| Production Capacity | 1000000PCS/Year |

Product Description

Solid Carbide High Performance Step Twist Drill Bits for Metal Drilling

Products Function

1.HRC: HRC45 HRC55 HRC58 HRC60 HRC652.Coated: AlTiN, TiAlN, TiAISI,TiSiN, TiN, DLC,Nano, Diamond3.Apply to:Could be used for the processing of plastic,wood, Aluminium.copper, cast iron, carbon steel, mould steel, stainless steel, taitanium alloy, tool steel, and heat-treated steel

Products Feature

- Special designed drill tip: Special designed drill tip will increase the Centering Ability and Chip breaker ability. Thus,the processing efficiency will be increased.

- Much sharper cutting edge: The much sharper cutting edge can decrease the cutting resistance and and torque. The lifetime of tools and machines will be longer.

- Heat-resistant coating: With highly heat-resistant HELICA/ALTIN coating, can be used for high-speed processing

- Smooth and wide flute:Smooth and wide flute will remove the cuttings more easily.

- High quality Raw Material: The raw material is used of high toughness, grain-sized carbon tungsten.

- Polished surface treatment: With high polished surface treatment, reduce the friction coefficient could be reduced, the lathe efficiency could be improved, more production time could be saved

D1 | D2 | L1 | L2 | L3 |

| 3.40 | 6.0 | 66 | 28 | 11.4 |

| 4.30 | 6.0 | 66 | 28 | 13.6 |

| 5.00 | 6.6 | 79 | 41 | 16.5 |

| 6.90 | 10.0 | 89 | 47 | 21.0 |

| 8.70 | 12.0 | 102 | 55 | 25.5 |

| 10.40 | 14.0 | 107 | 60 | 30.0 |

| 12.25 | 16.0 | 115 | 65 | 34.5 |

| 14.25 | 18.0 | 123 | 73 | 38.2 |

| Customized Tools are Acceptable | ||||

| Super Raw Material | |||

| HRC 45 | HRC 55 | HRC 60 | HRC 65 |

| YG10X | YL10.2&WF25 | Germany K44&K40 | Sandvik H10F |

| Grain size 0.7 μm,Co10%,Flexural strength 3320N/mm² | Grain size 0.6 μm,Co10%,Flexural strength 4000N/mm² | Grain size 0.5 μm,Co12%,Flexural strength 4300N/mm² | Grain size 0.5 μm,Co10%,Flexural strength 3320N/mm² |

| Super Coating | |||||

| Coating | HardnessHV | Thicknessμm | FrictionCoefficient | OxidationTemp | Color |

| AlTiN | 3500 | 2.5-3 | 0.3 | 900 | Black |

| TiAlN | 2800 | 2.5-3 | 0.3 | 900 | Violet |

| TiSiN | 3600 | 3 | 0.45 | 1000 | Bronze |

| AlTiSiN | 4000 | 3 | 0.4 | 1200 | Blue |

| TiN | 2500 | 2-3 | 0.5 | 600 | Gold |

Why trust us ?

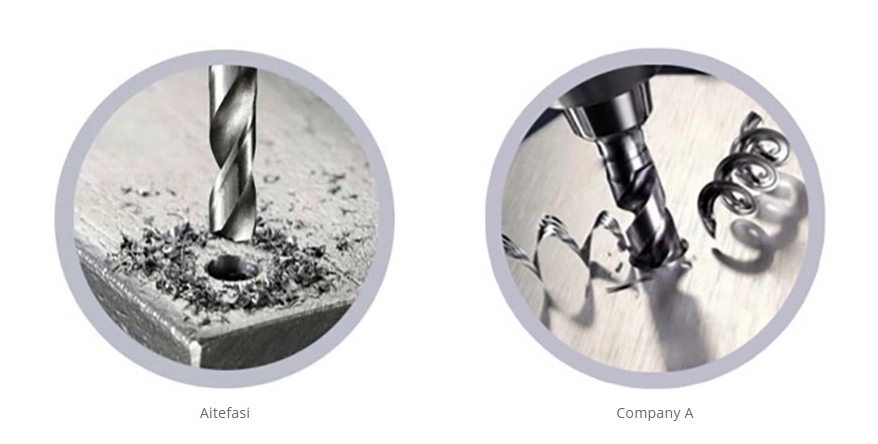

1...Chip breaker ability

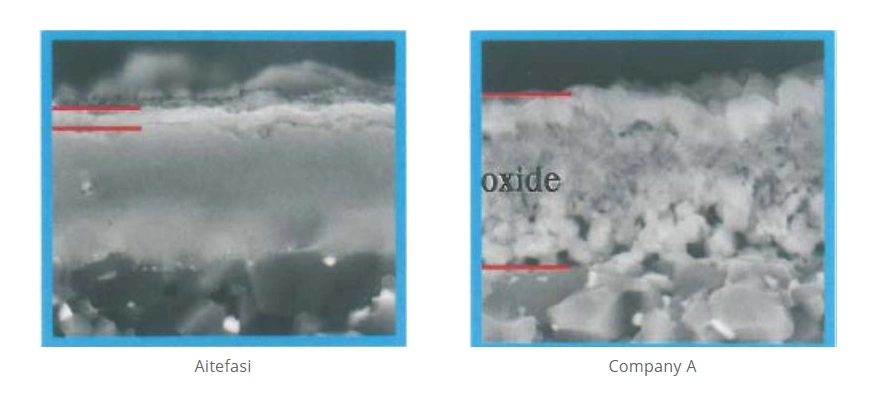

2..Perfect oxidation resistance in high temperature 1100ºC.

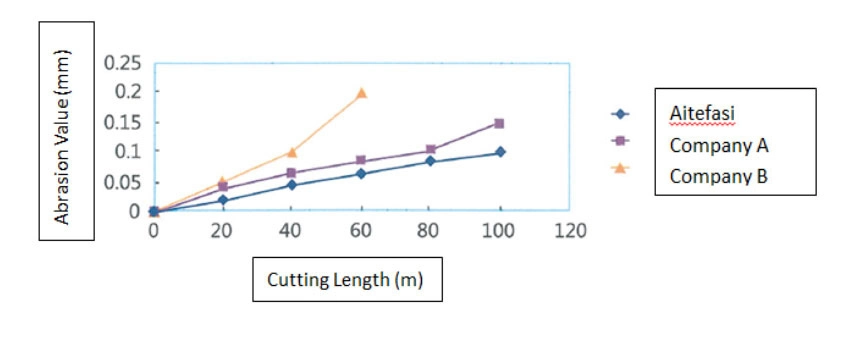

3. Abrasion condition of side cutting edge after processing 60m

Why trust us ?

What can we do for you ?

Quality Assurance OEM&ODM Our Service

Who are we ?

Who trust us ?

FAQ

Q: Are you trading company or manufacturer ?

A: we are the manufacturer Specializing in High-End carbide cutting tools and non-standard cutting tools, OEM&ODM accept;

Q: How long is your delivery time?

A: Generally 5- 15 working days, it depends ;Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer our stock sample for free charge and you please pay the cost of freight. custom cutting tools negotiated then we will quote the best sample cost

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.If you have another question, pls feel free to contact us.

Prev: 3/4/5/6/7/8mm Solid Carbide Drill Bits for Drilling Blind Wood Hole

Next: 3/16 to 7/8 Inch Step Drill Bit, M2 HSS Spiral Grooved Step Bit for Stainless Steel

Our Contact